International support services

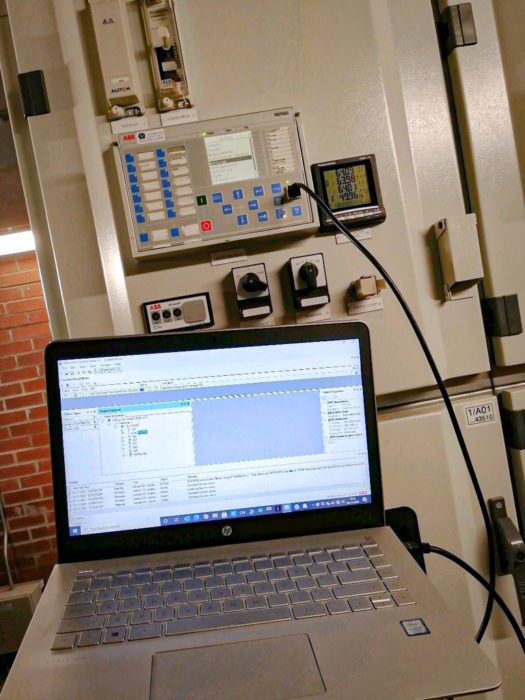

Improving the safety, reliability and efficiency of electrical assets with preventative maintenance

By keeping your assets correctly maintained, you can improve overall performance, operational reliability and safety levels. Thereby reducing the risk of any unexpected downtime and enhancing product life-cycle, saving you both time and money in the long run.

From switchboard and circuit breaker servicing, to protection testing and surveys, we have an extensive range of preventative maintenance services on offer which are guaranteed to keep your critical assets operating at their best.

Switchgear maintenance

Transformer maintenance

For critical assets like transformers, preventive maintenance is a must. This is to ensure any potential issues can be detected and acted upon at an early stage, in order to prevent further deterioration. Most importantly, to minimise the potential for unexpected, costly downtime periods.

Our highly skilled team of engineers are on hand to provide maintenance support for customers with transformers in their network, with services including but not limited to:

- Oil sampling + analysis

- Electrical measurements

- Replacement of silica gel crystals

- Inspection of all accessories and protection

- Comprehensive completion report and recommendations

Rotating machinery maintenance

Rotating machinery lies at the heart of most oil & gas processes, as they are relied on to perform daily operations and fulfil energy demands. Which is why the presence of aging equipment, variations in process conditions and the financial penalties incurred by downtime make it important to have a rigorous maintenance program in place.

By working closely with owners of rotating machinery, we provide specialist maintenance support by understanding the operating environment, performance and expections of a machine with regards to turnaround times and lifespan. From there, our experienced team of engineers can identify sources of degradation and assess potential mitigation efforts.

Standard services include, but are not limited to:

- Visual and dimensional inspections

- Wet magnetic particle inspection (MPI), ultrasound and liquid penetrant inspection

- Comprehensive work completion report and recommendations

UPS & Battery system maintenance

Every UPS (uninterruptible power supply) system has a battery that acts as a secondary/emergency power source where loss of primary power is identified. It’s therefore essential that batteries are properly maintained, to reduce chances of premature failure and ensure maximum level of protection.

Regular maintenance allows drops in battery life to be identified and remaining life-span accurately estimated. This enables planned maintenance and scheduled replacements to be carried out on a priority basis, without experiencing unexpected downtime or loss of backup power. In addition, preventive maintenance helps extend the life of battery strings, providing the opportunity to detect loose connections, remove corrosion and isolate bad batteries before they affect the entire string.

R&B Switchgear Group offer a safe, reliable maintenance service for UPS Battery systems, including but not limited to:

- Visually inspection and cleaning

- Safe disposal and replacement of “end of life” components

- Tightening of loose connections

- Periodic volt assessments and load testing to predict decreases in battery life

- Early planning of replacement cells

Surveys

Vast experience working across all types of switchgear and applications

Proudly supporting an international client base

Exceeding industry standards with ISO 9001, 14001, 45001, Achilles UVDB and Safe Contractor accreditations

Talk to us about your next project..

Our friendly team are on hand to discuss any upcoming projects and provide more information on our services and solutions. Get in touch today to explore what options are available to you.

OUR INDUSTRY EXPERIENCE

Keeping industries ticking with the ultimate support for critical power applications

Operating on an international scale, we have a wealth of experience delivering complex power distribution projects across the marine, offshore, energy, transport, defence and public service sectors. Our clients trust us and that’s why they choose to partner with us again and again.

Explore

Other Related Services

accreditations

Exceeding industry standards

We follow the industry’s leading governing bodies, and hold an impressive list of accreditations to demonstrate our commitment to cyber security, health and safety, quality and environmental excellence.